2l Rotovap

(1)1L/2L---Manual lifting with irony base/Manual lifting with SS base/Electric lifting

(2)3L/5L/10L/20L/30L/50L---Manual Lifting/Electric Lifting

***Price List for whole above, inquire us to get

2. Customization:

(1)Design support

(2)Directly supply the Senior R&D organic intermediate, shorten your R&D time and cost

(3)Share the advanced purifying technology with you

(4)Supply the high quality chemicals and analysis reagent

(5)We want to assist you on Chemical Engineering (Auto CAD, Aspen plus etc.)

3. Assurance:

(1)CE and ISO certification Registered

(2)Trademark: ACHIEVE CHEM(since 2008)

(3)Replacement parts within 1-year for free

Description

Technical Parameters

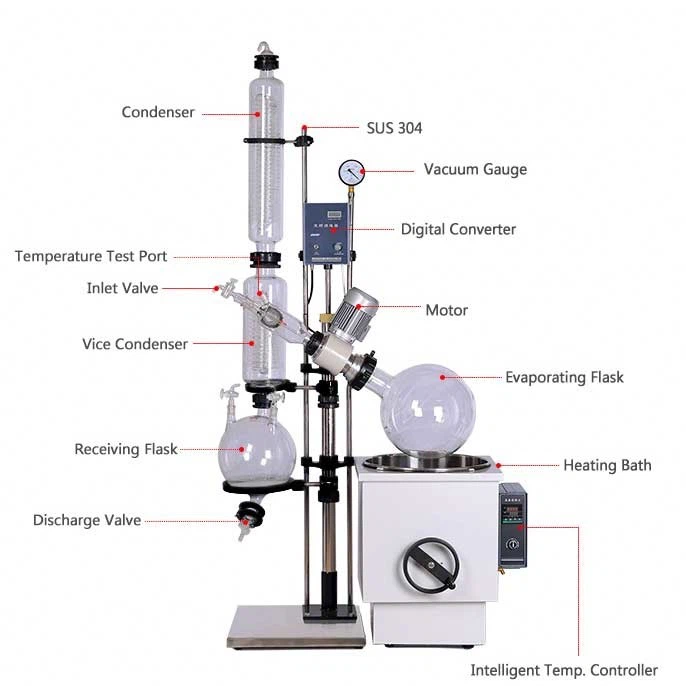

2L Rotovap is a laboratory equipment, also known as a rotary evaporator, mainly used for separation, concentration, and purification of chemical, biological, and other samples. It utilizes the difference in boiling points of components in the solution and gradually evaporates the solvent in the sample through slight heating and rotational motion under reduced pressure, thereby achieving separation and concentration.

The rotovap typically consists of a glass rotary flask and a distillation unit, which can hold the sample to be processed, while the distillation unit provides necessary heating and depressurization conditions. This device is widely used in laboratories in fields such as chemistry, pharmaceuticals, and food. This article will explain the heating method, vacuum degree, rotation speed, evaporation efficiency, and cooling method of 2L rotary evaporator.

Product Features

● Heating Method:

It is usually heated by electric heating. The equipment is equipped with an electric heating sleeve or furnace, which can provide the required heating power and temperature control.An electric heating sleeve is a heating device placed at the bottom of a rotating bottle, which conducts heat into the sample through current heating. It usually has temperature control function, which can set the required heating temperature and monitor and adjust the temperature in real time through temperature sensors.

An electric furnace is a heating device placed below a rotating bottle, usually containing a heating plate that can heat the surface of the rotating bottle through an electric current. Electric furnaces also typically have temperature control functions, which can be adjusted and monitored as needed.

Whether it is an electric heating jacket or an electric furnace, temperature control can be carried out according to experimental requirements to provide appropriate heating conditions and achieve the evaporation and separation of solvents in the sample.

● Vacuum Degree:

The vacuum degree of rotovap is usually determined by the vacuum pump equipped. The rotovap with different models or configurations may use different types and specifications of vacuum pumps, resulting in varying vacuum levels.Generally speaking, the vacuum degree of rotovap can reach a high level, usually within the range of 10 ^ -2 to 10 ^ -3 mbar. Some high-performance vacuum pumps can even provide lower vacuum levels, such as 10 ^ -4 to 10 ^ -5 mbar.

In experiments, it is usually necessary to adjust the vacuum degree according to the specific situation to achieve the best effect of sample evaporation and separation. A higher vacuum degree can promote rapid evaporation and separation of solvents, but excessive vacuum degree may lead to excessive drying or damage of the sample, so appropriate control and adjustment are needed in the experiment.It is worth noting that the exact value of vacuum degree is also influenced by other factors, such as sealing performance, leakage, etc. Therefore, it is necessary to maintain the equipment in good condition during operation to ensure a high vacuum degree.

● Rotation Speed:

The rotation speed of the 2L rotovap can be controlled by the motor below the rotating bottle. There is usually a speed control device on the device that can adjust the speed of the motor.The control of rotation speed is crucial for the evaporation efficiency and separation effect of the sample. A higher rotational speed can increase the surface area of the sample and the contact between the solvent and air, promoting the evaporation of the solvent. Meanwhile, appropriate rotation speed can also help maintain a uniform temperature distribution of the sample inside the rotating bottle.

The specific rotation speed range and control method may vary depending on the device model. Normally, the rotation speed can range from tens of revolutions per minute to hundreds of revolutions per minute, and can be adjusted according to experimental needs. There is usually a knob or button on the device for manually adjusting the rotation speed, and precise electronic control can also be achieved using a digital interface or remote control.

During the operation, it is necessary to choose an appropriate rotation speed based on the characteristics of the sample and experimental requirements. If the rotation speed is too fast or too slow, it may have adverse effects on the evaporation and separation effect, so appropriate debugging and optimization are needed.

● Evaporation Efficiency:

The evaporation efficiency of rotovap depends on multiple factors, including the properties of the sample, the boiling point of the solvent, the temperature of the evaporator, and the degree of vacuum.

Generally speaking, lower evaporator temperatures and higher vacuum levels can improve evaporation efficiency. By adjusting the temperature of the evaporator and the pumping speed of the vacuum pump, the evaporation rate of the solvent in the sample can be controlled. In addition, the surface area and stirring speed of the sample can also affect the evaporation efficiency.

However, it should be noted that different samples and solvents have different physical and chemical properties, so the evaporation efficiency may vary. Some samples may have high boiling points or viscosity, resulting in a relatively slow evaporation process. Therefore, in the experiment, it is necessary to optimize and adjust according to the specific situation to achieve the required evaporation efficiency.

|

|

● Cooling Methods:

There are usually two cooling methods for 2L Rotovap: water cooling and air cooling.

Water cooling

Water cooling is one of the common and widely used cooling methods. It uses an external water source and flows cold water through the condenser to lower the temperature through the cooling pipeline connected to the equipment. The condenser is a key component in a rotary evaporator, used to condense the evaporated gas into a liquid for recovery and collection. Cold water circulates through the pipes inside the condenser, absorbing heat and rapidly cooling the evaporated gas.

Air cooling

The air cooling method does not require an external water source, but uses natural convection or fan cooling to lower the temperature.

The device is usually equipped with a fan or heat sink to remove heat from the condenser through air flow. This method is more suitable for use without convenient water sources, but compared to water cooling, air cooling is usually not as effective as water cooling.

The choice of cooling method depends on the experimental requirements and environment. Water cooling can provide a more stable and efficient cooling effect, especially suitable for long-term operation and experiments under high temperature conditions. The air cooling method is more convenient and suitable for situations where there is no water source or no need for particularly low temperatures.

Regardless of the cooling method used, it is necessary to ensure the normal operation of the condenser and cooling system to effectively cool the evaporated gas and ensure the safety and stability of the equipment.

Product Advantage and Disadvantage

It is a common rotary evaporator, which has the following advantages and disadvantages compared to other types of rotary evaporators:

● Advantages:

Small size: The rotovap has a relatively small volume, occupies less space, and is easy to move and store.

Easy operation: The operation process of this device is relatively simple, and the experimental process can be completed by setting parameters such as rotation speed, temperature, and vacuum degree.

Strong controllability: The rotovap is equipped with advanced technologies such as digital display and electronic control, which can achieve precise temperature, pressure, and rotation speed control, making experimental results more stable and accurate.

Efficient and energy-saving: Due to the enclosed circulation system and efficient cooling technology of the equipment, rotovap can quickly recover solvents during the evaporation process, greatly improving work efficiency and saving energy

● Disadvantages:

Limited capacity:

Due to the limited capacity of rotovap, it cannot handle a large number of samples and is therefore not suitable for large-scale production or batch processing.

High cost:

Compared to other types of rotary evaporators, the cost of rotovap is higher, which to some extent increases the experimental cost.

Cannot handle high boiling point substances:

As the evaporation temperature of the equipment is usually between 30~90 ℃, it cannot handle high boiling point substances such as mineral oil.

In summary, 2L Rotovap has advantages such as small volume, simple operation, strong controllability, and high efficiency and energy conservation, but it has disadvantages such as limited capacity, high cost, and inability to handle high boiling point substances. When choosing to use a rotary evaporator, it is necessary to weigh and choose based on experimental requirements and budget.

Condensation efficiency

Definition of condensation efficiency

Condensation efficiency refers to the ability of the condenser in the rotary evaporator to cool the evaporated solvent vapor and condense it into a liquid. The high condensing efficiency means that more solvent vapor can be cooled and recovered quickly, increasing evaporation efficiency.

Factors affecting condensation efficiency

Condenser design

The shape, structure and material of the condenser will affect its condensing efficiency. For example, the vertical double serpentine tube condenser has a larger cooling area and a better cooling effect.

The flow mode of the cooling medium inside the condenser also affects the condensing efficiency. Good flow mode can ensure the uniform distribution of cooling medium and improve the condensation effect.

Cooling medium temperature

The lower the temperature of the cooling medium, the higher the condensation efficiency. Therefore, the use of equipment such as low-temperature coolant circulation pumps to reduce the temperature in the condensing pipe to below 0 ° C can significantly improve the condensing efficiency.

Vacuum degree

The higher the vacuum, the lower the boiling point of the solvent vapor, the faster the evaporation rate, and also help to improve the condensation efficiency. However, too high vacuum may lead to premature crystallization or combustion of the sample, so it needs to be adjusted according to the experimental requirements.

Solvent properties

Different solvents have different boiling points, volatility and heat capacity, which also affect the condensation efficiency. For example, a more volatile solvent has a higher condensation efficiency, while a solvent with a larger heat capacity has a lower condensation efficiency.

The method to improve the condensation efficiency

Choose the right condenser

Select the appropriate condenser shape, structure and material according to the experimental requirements and solvent properties to improve the condensing efficiency.

Reduce the cooling medium temperature

Use equipment such as cryogenic coolant circulation pumps to reduce the temperature in the condensing pipe to below 0 ° C to significantly improve the condensing efficiency.

Optimized vacuum degree

Adjust the vacuum according to the requirements of the experiment to ensure that the condensation efficiency is improved without premature crystallization or combustion of the sample.

Regular maintenance of the condenser

The condenser is cleaned and maintained regularly to ensure that its interior is unimpeded and the cooling medium can be evenly distributed, thereby improving the condensing efficiency.

Summary

The condensing efficiency of a 2L rotary evaporator is affected by many factors, including condenser design, cooling medium temperature, vacuum degree and solvent properties. In order to improve the condensing efficiency, users need to choose the right condenser, reduce the cooling medium temperature, optimize the vacuum degree and regularly maintain the condenser. Through these measures, the evaporation efficiency of the rotary evaporator can be effectively improved to meet the needs of the experiment.

Hot Tags: 2l rotovap, China 2l rotovap manufacturers, suppliers, factory, SS Reactor Manufacturer, Molecular Distillation Equipment, Short Path Molecular Distillation, Single Press Tablet Machine, SS316 Reactor, 5l Short Path Distillation

Previous

Large Scale RotovapSend Inquiry