What Temperature Should Rotovap Water Be?

Jul 11, 2024

Leave a message

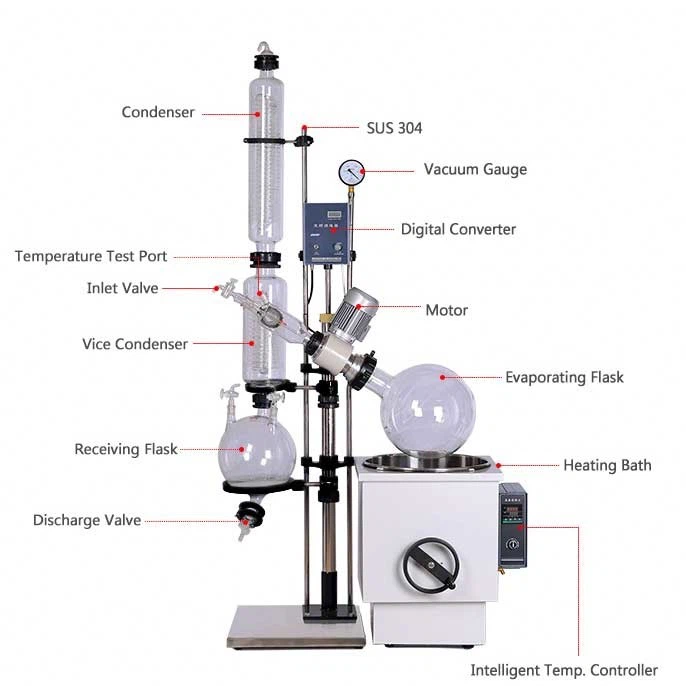

Rotary evaporators, commonly known as rotovaps, are essential tools in various scientific and industrial applications for solvent evaporation. One critical factor in their operation is the temperature of the water used in the condenser. Maintaining the correct water temperature ensures efficient evaporation and maintains the integrity of the substances being processed. The temperature of the water in a rotary evaporator's condenser plays a crucial role in its efficiency and the quality of the final product. Understanding the optimal temperature settings is essential for achieving desired results in various applications, from chemistry laboratories to industrial settings.

Why is Water Temperature Important in a Rotovap?

The temperature of the water used in the rotovap's condenser is critical due to its direct impact on the efficiency of solvent evaporation processes. Optimal water temperature management is essential to achieve desired outcomes in various scientific and industrial applications. Here's why water temperature plays a pivotal role:

- Condensation Efficiency: Water temperature directly influences how effectively solvent vapors condense back into liquid form. Lower temperatures enhance condensation efficiency by rapidly cooling and liquefying solvent vapors, which accelerates the evaporation process.

- Preservation of Heat-Sensitive Compounds: Many compounds, especially in pharmaceutical and chemical industries, are sensitive to high temperatures. Maintaining an optimal water temperature prevents excessive heat exposure during evaporation, preserving the integrity and functionality of these compounds.

- Control Over Evaporation Rate: Controlling the water temperature allows operators to regulate the evaporation rate precisely. This control is crucial for achieving specific concentrations and purities in the final product. It also ensures consistency and reproducibility in experimental and production settings.

- Efficient Heat Transfer: Proper water temperature ensures efficient heat transfer within the condenser. This efficiency minimizes energy consumption while maximizing the cooling effect, contributing to overall operational efficiency and cost-effectiveness.

What Happens if Rotovap Water Temperature is Too Low?

Maintaining an optimal water temperature in a rotary evaporator is crucial for efficient operation. When the water temperature in the rotovap condenser drops below the recommended levels, several adverse effects can occur:

- Reduced Efficiency of Condensation: Lower water temperatures slow down the condensation process. As a result, solvent vapors take longer to liquefy and collect in the receiving flask. This reduction in condensation efficiency prolongs the overall evaporation process, potentially delaying production schedules and experimental timelines.

- Risk of Solvent Freezing: Extremely low water temperatures can lead to the freezing or solidification of certain solvents. This phenomenon halts the evaporation process altogether, causing operational disruptions and potentially damaging equipment if ice forms within the condenser or tubing.

- Increased Energy Consumption: To compensate for low condensation rates caused by inadequate water temperature, operators may need to increase the energy input into the rotary evaporator. This additional energy requirement not only drives up operational costs but also may strain equipment components over time, leading to increased maintenance needs.

- Impact on Product Quality: Inconsistent or insufficient cooling due to low water temperatures can affect the quality and purity of the final product. Variations in evaporation rates and incomplete condensation may result in lower yields or compromised product integrity, particularly in sensitive applications such as pharmaceutical manufacturing or chemical synthesis.

- Operational Challenges: Low water temperatures can introduce operational challenges, such as difficulty in maintaining stable process conditions and achieving desired concentrations. Operators may need to frequently monitor and adjust parameters to mitigate the effects of inadequate cooling.

How to Optimize Rotovap Water Temperature for Different Solvents?

Optimizing the water temperature in a rotary evaporator (rotovap) is crucial for efficient solvent evaporation across various applications. The ideal water temperature varies depending on the solvent being processed:

- High Boiling Point Solvents: Solvents like chloroform or dichloromethane, which have higher boiling points, typically require lower water temperatures (around 10-15°C) in the condenser. Lower temperatures enhance condensation efficiency, ensuring that solvent vapors rapidly liquefy and are collected in the receiving flask. This temperature range balances effective condensation with the need to prevent excessive cooling that could impede the process.

- Low Boiling Point Solvents: Solvents such as ethanol or acetone, with lower boiling points, necessitate colder water temperatures (below 10°C) for optimal performance. Cold water aids in quickly cooling and condensing these volatile solvents, maintaining high evaporation rates and efficiency. This adjustment is critical to prevent solvent loss through vapor escape and to achieve precise concentration and purity goals.

Considerations for Optimization

When optimizing water temperature for different solvents in a rotary evaporator:

- Solvent Characteristics: Understand the specific boiling points and thermal properties of each solvent. This knowledge informs the selection of an appropriate water temperature range that balances effective condensation with solvent volatility.

- Evaporation Rate Control: Adjust water temperature to regulate the evaporation rate according to production or experimental requirements. This control ensures consistent performance and reproducibility in solvent recovery and concentration processes.

- Monitoring and Adjustment: Regularly monitor and adjust water temperature settings based on real-time feedback from the condenser's performance. This proactive approach optimizes operational efficiency and minimizes the risk of solvent loss or degradation.

Benefits of Optimization

Optimizing water temperature based on solvent characteristics offers several benefits:

- Enhanced Efficiency: Improves condensation rates and reduces overall evaporation times, enhancing operational throughput and productivity.

- Maintained Product Quality: Preserves the integrity of heat-sensitive compounds and ensures consistent product quality across batches.

- Cost Effectiveness: Reduces energy consumption by optimizing cooling requirements, contributing to lower operational costs over time.

Conclusion

Choosing the correct water temperature for a rotary evaporator is crucial for achieving efficient solvent evaporation and maintaining product integrity.

By understanding the impact of water temperature on condensation efficiency and solvent properties, operators can optimize their processes to meet desired outcomes effectively.