What Is Centrifugal Distillation

Oct 11, 2023

Leave a message

There is no specific term "centrifugal distillation" in chemistry. However, there is a technique called centrifugal molecular distillation which is a type of liquid-liquid separation technique that utilizes centrifugal force to promote molecular evaporation of the samples being separated. This technique is widely used in the chemical, pharmaceutical, and food industries for the purification, refining, and separation of various chemical compounds.

In centrifugal molecular distillation, a mixture is placed in a rotating cone-shaped evaporator, and heated under vacuum. The rotation creates a centrifugal force field that spreads the mixture into a thin layer on the surface of the evaporator, which greatly enhances the mass transfer rate and evaporation efficiency. Due to the different boiling points and vapor pressures of the components in the mixture, they will evaporate at different rates. The more volatile components with lower boiling points will evaporate faster and be collected in a condenser, while the less volatile components with higher boiling points will remain in the evaporator. In another word, centrifugal molecular distillation is a powerful tool for separating and purifying complex mixtures of organic compounds with high boiling temperatures, including oils, polymers, and biofuels.

The centrifugal method, in general, refers to the application of centrifugal force to separate substances or particles based on their differences in density. It is widely used in various industries for separation purposes. In the context of centrifugal molecular distillation, the centrifugal method is employed to create a force field that enhances the molecule's evaporation and transport, facilitating the separation of components with different boiling points and vapor pressures. The centrifugal force field aids in increasing the surface area for evaporation, improving mass transfer rates, and ultimately enhancing the efficiency of the separation process.

The principle of centrifugal molecular distillation, also known as centrifugal molecular still, is based on the application of centrifugal force to enhance the separation and purification of liquid mixtures. This technique utilizes the difference in boiling points and vapor pressures of components in a mixture to achieve efficient separation.

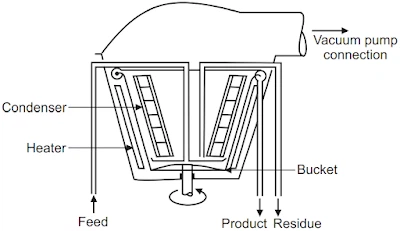

The centrifugal molecular distillation apparatus consists of a rotating cone-shaped evaporator, a condenser, and a vacuum system. The mixture to be separated is introduced into the evaporator, which is rapidly rotated. As a result of the rotation, the liquid forms a thin film on the inner surface of the evaporator, increasing the surface area available for evaporation. Simultaneously, a vacuum is applied to lower the pressure inside the system, thereby reducing the boiling points of the components.

The centrifugal force generated by the rotation of the evaporator causes the lighter and more volatile components to migrate towards the inner surface of the evaporator. This, in turn, increases their chances of evaporation. As the components evaporate, they rise to the top of the evaporator and enter the condenser, where they are cooled and condensed back into a liquid state. The condensed vapor is collected separately, resulting in the separation of components based on their volatility and boiling points.

The component equipment of centrifugal molecular distillation typically consists:

1. Rotating cone-shaped evaporator: This is the core component of the centrifugal molecular distillation setup. The evaporator is designed in a cone shape and is rapidly rotated during operation. It provides a large surface area for the liquid mixture to spread out as a thin film, facilitating efficient evaporation. The rotating cone-shaped evaporator is crucial in chemical reactions because it increases the contact area between the reactants and promotes efficient heat transfer. The thin film formation enables improved mass transfer and enhances the separation of components with different boiling points.

2. Condenser: The condenser is responsible for cooling the vaporized components from the evaporator and turning them back into a liquid state. It consists of a cooling system that helps remove heat from the vapor, causing condensation. The condenser plays an essential role in maintaining the separation efficiency of the centrifugal molecular distillation process. It ensures that the vaporized components are collected separately, enabling the purification and isolation of desired compounds.

Vacuum system: The vacuum system serves to lower the pressure inside the centrifugal molecular distillation apparatus. By reducing the pressure, the boiling points of the components are lowered, promoting easier evaporation even at lower temperatures. The vacuum system is critical in chemical reactions as it allows for precise control over the pressure conditions during distillation. It enables the separation and purification of sensitive or high-boiling-point compounds that may decompose or degrade under normal atmospheric pressure conditions

Common applications of centrifugal molecular distillation include:

1. Fractionation and purification of oils: It is used in the refining of edible oils, essential oils, and petroleum products to obtain highly purified fractions with specific properties.

2. Separation of heat-sensitive compounds: Centrifugal molecular distillation is employed in the separation of thermally sensitive compounds such as vitamins, fatty acids, and pharmaceutical intermediates.

3. Purification of high-boiling-point compounds: It is utilized for the purification and isolation of high-boiling-point compounds like waxes, polymers, and resins.

4. Recycling of solvents: Centrifugal molecular distillation enables the recovery and recycling of solvents from industrial processes, reducing waste and improving sustainability.

5. Cannabis and hemp processing: It is used in the extraction and purification of cannabinoids, terpenes, and other valuable compounds from cannabis and hemp plants.

Centrifugal molecular distillation offers a versatile method for separating complex mixtures and purifying substances, finding applications in various industries requiring high-quality refined products.

Centrifugal molecular distillation possesses have several unique features:

1. Efficient separation: Centrifugal molecular distillation allows for the efficient separation of components with very close boiling points or similar chemical properties. By applying centrifugal force and creating a thin film, the technique enhances the surface area available for evaporation, leading to improved mass transfer and separation efficiency. This is especially crucial when dealing with complex mixtures containing highly volatile and sensitive compounds.

2. Mild operating conditions: Centrifugal molecular distillation operates under reduced pressure and at lower temperatures compared to conventional distillation methods. This is due to the vacuum system employed, which lowers the boiling points of the components. The ability to carry out distillation at lower temperatures helps preserve the integrity of heat-sensitive compounds that may decompose or degrade under higher temperatures, making it suitable for separating thermally labile substances.

3. Short processing time: The combination of centrifugal force, thin film evaporation, and reduced pressure allows for faster separation compared to traditional distillation techniques. The increased surface area promotes quick vaporization and condensation of the components, reducing processing time and increasing productivity.

4. High purity and quality: Centrifugal molecular distillation enables the production of highly purified compounds, as it provides excellent separation efficiency and minimizes the risk of cross-contamination. The method is particularly valuable in industries such as pharmaceuticals, essential oils, and food processing, where achieving high purity and quality standards is essential.

5. Scalability: Centrifugal molecular distillation can be easily scaled up for industrial production. The equipment can handle large volumes of liquid mixtures while maintaining efficient separation and maintaining consistent product quality. This scalability makes it adaptable to various manufacturing processes.

Overall, the uniqueness of centrifugal molecular distillation lies in its ability to achieve efficient separation of complex mixtures under mild conditions, resulting in high-purity products. It plays a vital role in chemistry by enabling the purification of sensitive compounds, facilitating the extraction of valuable substances, and contributing to the production of high-quality materials in various industries.