50 Ml Centrifuge Machine

Description

Technical Parameters

50 ML centrifuge machine is a mechanical device that uses centrifugal force to separate components from liquid and solid particles or mixtures of liquids. Centrifuges are mainly used to separate solid particles from liquids in suspensions, or to separate two immiscible liquids with different densities in emulsions (such as separating cream from milk); It can also be used to remove liquids from wet solids, such as using a washing machine to spin dry and wet clothes; The special high-speed tube separator can also separate gas mixtures of different densities; By taking advantage of the different settling velocities of solid particles with different densities or particle sizes in liquids, some settling centrifugs can also classify solid particles according to density or particle size.

Basic Principles and Classification

1. Principle of centrifugal separation

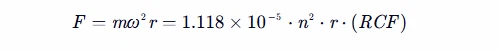

Centrifuges generate centrifugal force fields through high-speed rotation, utilizing the density differences of different substances to achieve separation. The formula for calculating centrifugal force is:

Among them, RCF (relative centrifugal force) is the core parameter, and a 50ml centrifug typically provides a range of 2000-15000 × g, suitable for the separation of cell debris, proteins, DNA, etc.

2. Rotor type and adaptability

Fixed angle rotor:

The bottom of the tube is at a fixed angle (such as 45 °) to the rotating axis, suitable for high-density sample separation, with a tube size of 4-6 × 50ml.

Horizontal rotor:

The test tube is parallel to the axis of rotation and used for density gradient centrifugation. The number of tubes is 8 × 50ml.

Vertical rotor:

The test tube is perpendicular to the axis of rotation, suitable for large capacity processing, with 2 x 50ml tubes.

Airtight rotor:

Supports low-temperature centrifugation and is equipped with a biosafety sealing cover to prevent sample leakage.

3. Classification of Temperature Control Systems

Room temperature centrifuge:

No refrigeration system, suitable for conventional separation tasks.

Low temperature centrifuge:

Equipped with a built-in compressor unit, with a temperature control range of -20 ℃ to 4 ℃, to protect temperature sensitive samples (such as RNA and enzymes).

Ultra low temperature centrifuge:

Supports operation at -80 ℃, equipped with a vacuum insulation layer, for long-term preservation of samples.

Main advantage

50 ML centrifuge machine is a machine that uses centrifugal force to accelerate the separation of different materials that need to be separated. Centrifugs are widely used in various sectors such as chemical, petroleum, food, pharmaceutical, mineral processing, coal, water treatment, and shipbuilding.

The main principle of a filtration centrifug is to use the centrifugal force generated by a high-speed rotating centrifugal drum (with appropriate filter materials) to accelerate the liquid phase in the solid-liquid mixture and throw it out of the drum, while keeping the solid phase inside the drum, achieving the effect of separating solids and liquids, or commonly known as dehydration.

The main principle of a settling centrifug is the strong centrifugal force generated by the high-speed rotation of the rotor, which accelerates the settling speed of different specific gravity components (solid or liquid phase) in the mixed liquid, and separates substances with different settling coefficients and buoyancy densities in the sample.

Centrifugs are widely used in sectors such as mineral processing, coal, water treatment, and shipping.

The selection of a centrifug should be based on the size and concentration of solid particles in the suspension (or emulsion), the density difference between the solid and liquid (or two liquids), the viscosity of the liquid, and the characteristics of the filter residue (or sediment). You can refer to the "Selection and Safe Use of Centrifugs [Selection Guide]".

Model

50 ML centrifuge machine can be divided into two types: industrial centrifuges and experimental centrifuges

Not Just Traditional Cyber & Immigration Firm

Industrial centrifugs can generally be divided into filtration centrifuges, piston push centrifugs, disc centrifugs, sludge dewatering machines, suspended centrifuges, gravity discharge centrifuges, etc

Experimental centrifuges can be used for liquid clarification and solid particle enrichment, or liquid-liquid separation. These types of centrifugs have different structural forms for operation under atmospheric pressure, vacuum, and freezing conditions. The main models include desktop medical high-speed centrifugs, laboratory low-speed centrifugs, and large capacity cryogenic centrifugs, which are generally used in experimental extraction in hospitals or schools. They are also called electric centrifugs. The working principle of centrifugs is basically the same, but the speed of these centrifugs is generally above 3000 revolutions per minute, much higher than that of industrial centrifugs. The manufacturers are mainly concentrated in Changsha, Hunan.

GF - Separation type: mainly used for separating various difficult to separate emulsions, especially suitable for liquid-liquid separation with minimal density difference between phases (specific gravity difference greater than 0.1%), as well as liquid-liquid solid three-phase separation containing small amounts of impurities. Separation of oil products, dehydration and dewaxing of transformer oil, edible oil, turbine oil, biodiesel, coal tar, lubricating oil, marine fuel oil, quenching oil; Separation of various syrup agents; Whole blood separation - separating plasma and blood cells from whole blood; Separation of biological products; Oil water separation, sewage treatment, etc.

GQ - Clarifying tube centrifuge, mainly used for separating various difficult to separate suspensions, especially suitable for solid-liquid separation with low concentration, high viscosity, fine solid particles, and small solid-liquid density difference.

For example, traditional Chinese medicine oral liquids have high sugar content, many flocculent substances, fine solid particles, and a small difference in solid-liquid specific gravity.

Usage guidelines

Rules

When the centrifuge is in the pre cooling state, the centrifuge cover must be closed. After centrifugation, the rotor removed should be inverted on the experimental table, and the remaining water in the chamber should be wiped dry. At this time, the centrifuge cover is in the open state.

When pre cooling the rotor, the rotor cover can be placed on the platform of the centrifuge or on the experimental bench. It must not be left loose and floating on the rotor because if it is accidentally started, the rotor cover will fly out, causing accidents!

After tightening the rotary head cover, be sure to touch the gap between the rotary head and the cover with your fingers. If there is a gap, unscrew and tighten it again until it is confirmed that there is no gap before starting the centrifuge.

During the centrifugation process, the operator must not leave the centrifuge chamber. In case of any abnormal situation, the operator cannot turn off the power (POWER) and must press STOP. Before pre cooling, it is necessary to fill out the centrifuge usage record.

Do not use counterfeit centrifuge tubes, and do not use centrifuge tubes that are aging, deformed, or have cracks.

During holidays and evenings, the last person to use the centrifuge must undergo a routine safety check before leaving.

In case of machine failure or component damage during the use of the instrument, it is necessary to promptly contact the manufacturer.

Precautions for use

The commonly used electric 50 ml centrifuge machine in the laboratory has a fast rotation speed. It is important to pay attention to safety, especially to prevent the centrifuge from moving while working due to imbalance or aging of the test tube pad during operation, which may cause it to fall off the experimental bench, or the centrifuge tube to break due to vibration caused by uncovered lid, resulting in glass fragments rotating and flying out, causing accidents. Therefore, when using a centrifuge, the following operations must be noted.

The bottom of the centrifuge casing should be padded with cotton or test tube pads.

If there is noise or body vibration in the electric centrifuge, the power should be cut off immediately and the fault should be eliminated immediately.

The centrifuge tube must be symmetrically placed in the casing to prevent vibration of the machine body. If there is only one sample tube, the other should be replaced with water of equal mass.

When starting the centrifuge, cover the top cover of the centrifuge before slowly starting it.

After the separation is completed, turn off the centrifuge first. After the centrifuge stops rotating, open the centrifuge cover and take out the sample. Do not force it to stop moving with external force.

The centrifugation time is generally 1-2 minutes, during which the experimenter must not leave to do anything else.

Low speed experimental centrifuges with a speed of around 3000 revolutions per minute are commonly used in enterprises or research institutions, such as the 315 type filtration and sedimentation integrated experimental centrifuge, the 100 type experimental centrifuge, and the 200 type experimental centrifuge. These centrifuges are designed reasonably, have a low center of gravity, are safe and stable, and have been widely used in the early sample analysis of chemical, food, medical and other fields.

Hot Tags: 50 ml centrifuge machine, China 50 ml centrifuge machine manufacturers, suppliers, factory, Rotating Evaporator, Short Path Molecular Distillation, Double Layer Glass Reactor, High Pressure Stainless Steel Reactor, 20 Liter Rotary Evaporator, Multi Station Rotary Press

Previous

Food Centrifuge MachineSend Inquiry